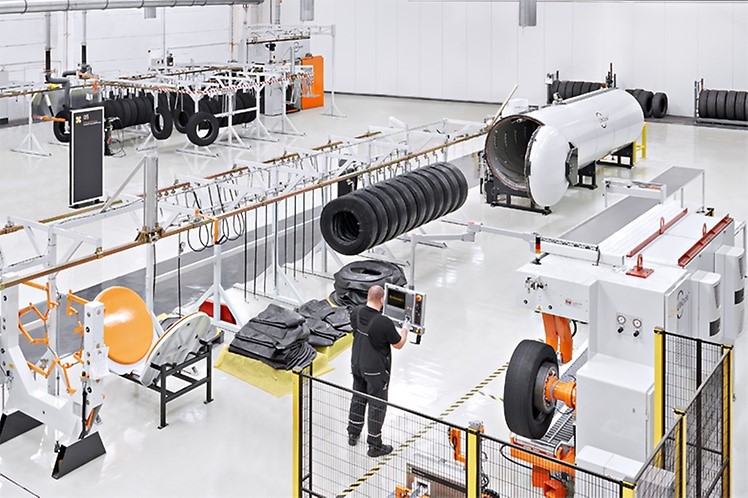

TRM Srl (Tyre Retreading Machinery ) develops and manufactures the most sophisticated and technologically advanced systems for tire retreading.

For more than 35 years the Italian manufacturer has delivered solutions for all tire segments (passenger, truck, aircraft, and OTR) and retread systems by offering tailored solutions for clients worldwide.

Shamrock is the authorized distributor of the Latitude Series of equipment by TRM in North America.

The Latitude line is designed specifically for the U.S. market with a focus on automation.

TRM’s objective with the Latitude Series of equipment is to help retreading be more competitive with cheap new tires by moving the retread process towards automation.

Requiring fewer plant technicians also helps retreaders overcome many of the labor challenges they face today.

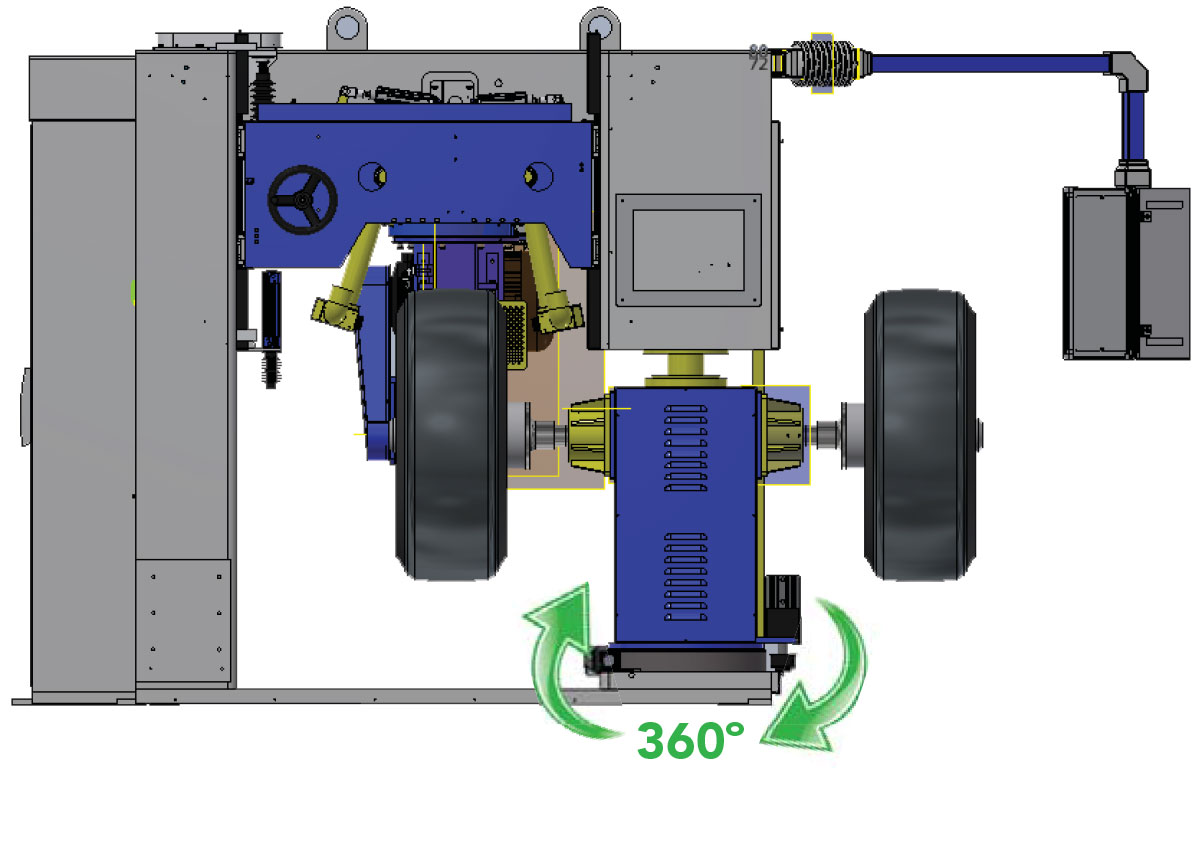

BUFFING

EAGLE TWIN BUFFER by TRM

KEY FEATURES

BENEFITS

EAGLE TRUCK 2500 by TRM COMPUTERIZED BUFFING MACHINE

KEY FEATURES

LATITUDE 1500 TREAD BUILDER by TRM

KEY FEATURES

BLACK SWAN 3000 by TRM

FOR CUSHION GUM APPLICATION

Automatic extruder machine developed for the tire retreading industry and designed to fit the extruded cushion gum in strips on the tire casings to be retreaded. The machine is able to carry out the following operations:

LATITUDE PRESSURE TESTER

KEY FEATURES